Table of Contents

- 1. An Industrial Arm That Combines Power and Precision

- 2. A Robot That Sees More Than a Human

- 3. Not Just Assembly – Also Welding and Machining

- 4. Intelligent System Integration

- 5. Interesting Fact: A Robot That Learns

- 6. High reliability in all conditions

- 7. A Fascinating Fact from the Factory – A Robot That Welds with a Partner

- 8. Where is the Fanuc M-20iA/35M most often used?

- 9. A Robot That Assists People

The Fanuc M-20iA/35M robot combines power, precision, and intelligent automation. This six-axis manipulator is ideal for assembly, welding, and CNC operations, ensuring reliability and efficiency in any industrial sector.

1. An Industrial Arm That Combines Power and Precision

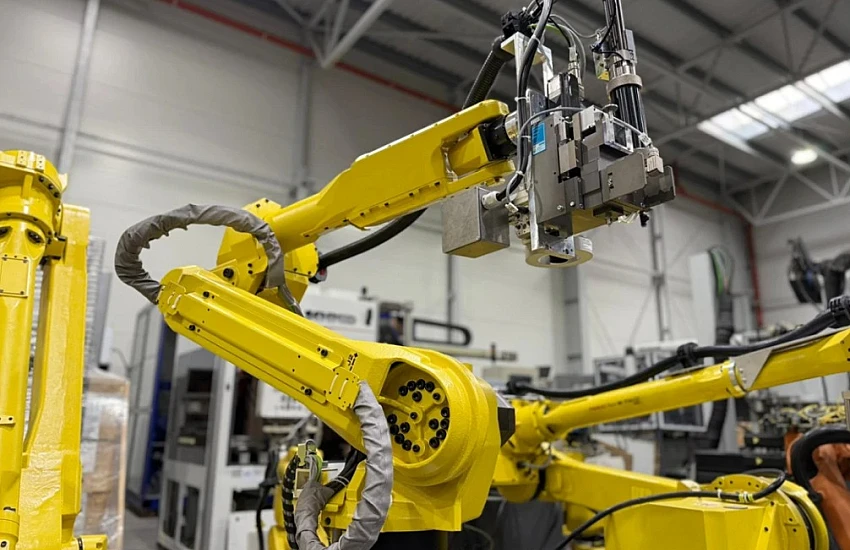

The Fanuc M-20iA/35M robot exemplifies how far production automation has come. This six-axis industrial arm performs even the most demanding tasks with extraordinary precision – from assembly and component handling to welding and packaging.

Every movement of this six-axis manipulator is controlled to within hundredths of a millimeter thanks to a modern motion controller that analyzes data in real time.

As a result, the M-20iA/35M not only repeats programmed actions – it can also respond to changes in the environment and dynamically adjust operating parameters.

2. A Robot That Sees More Than a Human

One of the robot's most interesting design elements is its 2D and 3D vision sensors.

Thanks to these features, the Fanuc M-20iA/35M can "see" an object, recognize its location, and even determine the force required to safely lift it.

Combined with a precision pneumatic gripper, the robot can manipulate objects of varying shapes, weights, and textures – from delicate electronic boards to massive metal components.

This combination of vision and touch allows the device to independently adapt to the conditions – without the need for constant operator intervention.

3. Not Just Assembly – Also Welding and Machining

While many associate the M-20iA/35M primarily with assembly and component transport, this model is also used in welding and machining processes.

Its industrial arm has increased rigidity and stability, enabling precise guidance of a welding torch or cutting tool.

In plants where repeatability and weld quality are essential, these robots achieve results that would be difficult to achieve manually – especially when operating 24/7.

This is why the M-20iA/35M is often used in mass production, where speed, repeatability, and minimal errors are key.

4. Intelligent System Integration

The Fanuc M-20iA/35M is designed to easily interface with other devices in the plant.

Thanks to its open architecture and the ability to communicate with various industrial protocols, its system integration with CNC machines, conveyors, and vision scanners is quick and seamless.

Furthermore, the robot can be part of a comprehensive smart manufacturing environment, where all components—from sensors to ERP software—exchange data in real time.

This solution enables efficiency analysis, predictive maintenance, and automatic adjustment of production parameters to current demand.

5. Interesting Fact: A Robot That Learns

Although the M-20iA/35M is not a collaborative robot (so-called cobot), it can learn new tasks through teaching-by-demonstration.

The operator can physically guide the arm along a memorized trajectory. The robot then records the movements and repeats them fully automatically.

Combined with vision sensors and environmental data analysis, this allows for the rapid implementation of new processes – for example, changing a part, welding pattern, or packaged product type.

6. High reliability in all conditions

One of the greatest advantages of the Fanuc M-20iA/35M is its durability.

The device can operate in dusty, high-humidity, and elevated-temperature environments while maintaining full motion accuracy.

This is thanks to the hermetic axis design and the use of corrosion- and vibration-resistant components.

This makes the M-20iA/35M frequently used in demanding industries such as the metal, automotive, and food industries.

It not only increases productivity but also enhances safety and quality during production line modernization processes.

7. A Fascinating Fact from the Factory – A Robot That Welds with a Partner

In modern industrial plants, systems in which two M-20iA/35M robots work side-by-side are becoming increasingly common.

One manipulator feeds components, while the other performs the welding – all fully synchronized by a shared motion controller.

Such a duo can perform hundreds of identical welds per hour with precision unattainable by a human operator.

This is an excellent example of the practical application of system integration and machine collaboration in smart manufacturing.

8. Where is the Fanuc M-20iA/35M most often used?

This robot is used in many industries.

Here are some examples:

- Automotive – assembly of body parts, frame welding, and transportation of metal components

- Electronics – precision assembly of PCBs and microelectronic components

- Household appliances – assembly and packaging of electronic modules, housings, and panels

- Metallurgy – cutting, welding, and polishing of steel components

- Pharmaceuticals and cosmetics – packaging, labeling, and product sorting

- Logistics and warehousing – automated loading, sorting, picking, and palletizing

Each of these applications confirms that the M-20iA/35M is a universal solution that can be easily adapted to the specific production requirements.

9. A Robot That Assists People

Although automation is often associated with replacing workers, robots like the M-20iA/35M actually support people, relieving them of the most monotonous, repetitive, and dangerous tasks.

As a result, operators can focus on process control, programming, and data analysis.

This is an example of human-machine collaboration, where both parties benefit – the human benefits from safety and comfort, and the plant benefits from improved efficiency and quality.

10. Summary

The Fanuc M-20iA/35M robot is more than just an industrial arm – it's the technological centerpiece of a modern factory.

It combines mechanical precision, intelligent vision sensors, pneumatic grippers, and advanced system integration, becoming the heart of production automation and smart manufacturing processes.

Thanks to its versatility, it's suitable for both line modernization and new industrial implementations.

This proves that the future of automation is not just about efficiency – it's, above all, about technology that thinks alongside people.