Table of Contents

KUKA KS QuadroSpin is an innovative positioning system designed for automated production lines. It enables fast and precise rotation of large workpieces, ensuring full synchronization with industrial robots. Thanks to its compact design, high load capacity and reliability, QuadroSpin is ideal for the automotive, household appliances and steel construction industries. Increase the efficiency and flexibility of your production - rely on proven KUKA technology.

1. Introduction

History of KUKA

KUKA is a German company founded in 1898 in Augsburg, known worldwide as a pioneer in the field of industrial automation and robotics. Initially producing gas lighting, it has gradually transformed into a global leader in robotic technology, introducing the world's first industrial robot with six axes - FAMULUS - in 1973.

What is KUKA KS QuadroSpin?

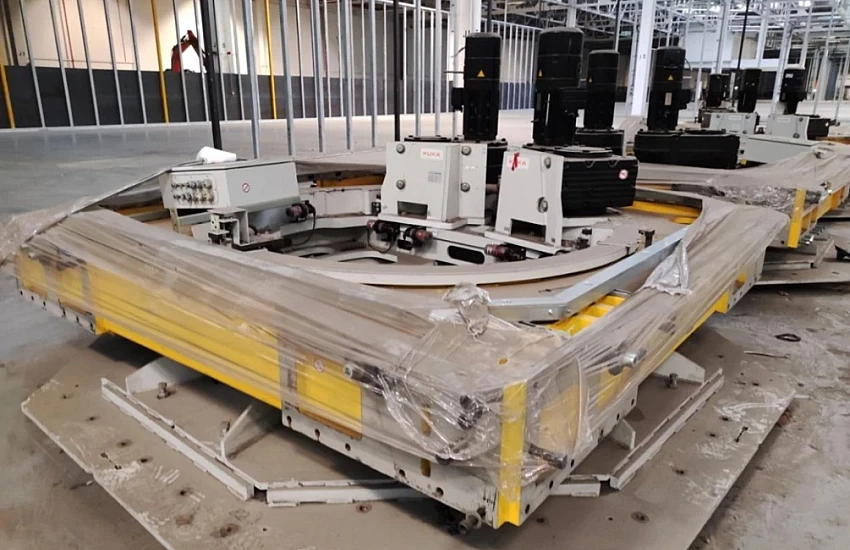

KUKA KS QuadroSpin is a modern rotation and positioning system designed for integration with industrial robots. It is an advanced unit with four axes of movement, created for precise positioning of elements during welding automation and other technological processes.

2. Advantages of the KUKA KS QuadroSpin rotation system

KUKA KS QuadroSpin is a solution that stands out from classic positioners thanks to the combination of high precision, modular design and full system integration with KUKA robots. Here are the most important advantages of this unit:

Precise positioning in 4 axes

The advanced design of QuadroSpin enables precise positioning of parts in many planes, which translates into the quality and repeatability of robotic processes. The key role here is played by the rotary axis, which allows for the rotation of even very heavy elements.

Compact and modular design

KUKA KS QuadroSpin is characterized by a compact design, which facilitates its implementation even in limited space in the production hall. Thanks to its well-thought-out geometry and optimized dimensions, the device can be integrated into an existing line without the need for its major reconstruction.

The modular design allows for flexible adjustment of the positioner configuration to specific process needs - e.g. the number and type of geotools installed or the control method (manual or automatic). This approach allows for quick scaling of the solution, its relocation between stations or expansion of the system with the development of production. As a result, the company gains not only technological versatility, but also real savings related to the implementation time, workspace and investment costs.

High load capacity and stability

KUKA KS QuadroSpin was designed to handle heavy, bulky and non-standard workpieces, the weight and shape of which pose a challenge for conventional positioners. Its solid steel frame and optimized weight distribution guarantee maximum stability during workpiece rotation, even with dynamic position changes. Thanks to its high load capacity (up to 14,000 kg), the device provides full control over high-inertia elements, eliminating the risk of shifts or vibrations affecting the quality of processing.

Such properties are particularly important in processes where positioning accuracy relative to the robot tool is important – e.g. in welding steel structures, machine components or industrial infrastructure elements. As a result, QuadroSpin enables safe, repeatable and precise work even in the most demanding production conditions.

Integrated control with the robot

QuadroSpin works directly with KUKA control systems, ensuring full integration with robot arms within a single operating platform. This enables central programming and precise synchronization of the positioner and robot movements in real time. This significantly simplifies the configuration of complex robot cells and shortens the implementation time. The operator can control all axes from a single KUKA SmartPad interface, which increases ergonomics and reduces the risk of errors.

Reduction of cycle times

Thanks to smooth positioning, the device affects the overall production efficiency by reducing the time needed to switch between work steps. As a result, a higher number of cycles per hour can be achieved, which translates directly into increased productivity and cost-effectiveness of production.

Low operating costs

The well-thought-out design minimizes component wear, supporting long-term optimization of the production process. High-quality mechanical components, such as SEW gear motors or reinforced bearing elements, ensure a long service life and reliability under intensive use. In addition, easy access to technical components simplifies maintenance, reducing downtime.

3. Key Features and Technical Specifications

Below we present the detailed technical specifications of the KUKA KS QuadroSpin system, containing all the key technical parameters important for integrators and production engineering departments.

Technical specifications:

- Condition: Brand new

- Quantity: 4 pieces

- Year of production: 2014

- Internal diameter: 2200 mm

- Weight: 7500 kg

- Load capacity: up to 14,000 kg

- Possibility of mounting geotools: up to 4 pieces

- Drive: two SEW FAZ107/R gear motors

- Control: control cabinet included

- Table rotation: 90° or 180° (manually or automatically depending on configuration)

4. Industrial applications

KUKA KS QuadroSpin was designed for use in demanding industrial environments where precision, repeatability and maximum operational efficiency are essential. Thanks to its robust design, high load-bearing capacity and integration with KUKA robots, the system can be used in many industries.

Below we present the most common areas of QuadroSpin application, along with practical examples:

Metal industry

In metalworking plants, KUKA KS QuadroSpin supports welding, assembly and machining processes of steel structures. It enables precise positioning of heavy components, which translates into the quality of joints and reduced production errors. This system is used, among others, in the production of steel support frames, brackets or lifting elements.

Large-scale production

Thanks to its robust design and high load-bearing capacity, QuadroSpin is ideal for working with large components – e.g. machine frames, pressure vessels or industrial infrastructure components.

Automotive and automotive

The device works great in series production, where repeatable and fast positioning of elements such as frames, bodies or components is required.

Machinery and construction industry

In the production of machines, devices and steel structures, KUKA KS QuadroSpin improves the manipulation of elements with irregular shapes. It enables stable and safe positioning during machining, welding or assembly.

Thanks to four-axis control, it is possible to precisely position parts with complex geometry, such as transport frames, components of construction machines or supporting structures of industrial machines.

Energy and heavy industry

The device also works well in sectors requiring the processing and joining of large, heavy parts - e.g. in the production of turbine components, industrial boilers or pressure systems.

5. Summary

KUKA KS QuadroSpin is a technologically advanced four-axis positioner that sets new standards in the automation of production processes. It combines high precision, solid construction and full compatibility with KUKA robots, making it an irreplaceable solution in modern industrial lines.

Thanks to its modular design, high load capacity and versatility of applications, QuadroSpin is suitable for both large-scale production and sectors requiring the highest quality and repeatability. This is a technology that is actually turning the industry towards greater efficiency, automation and competitive advantage.