Table of Contents

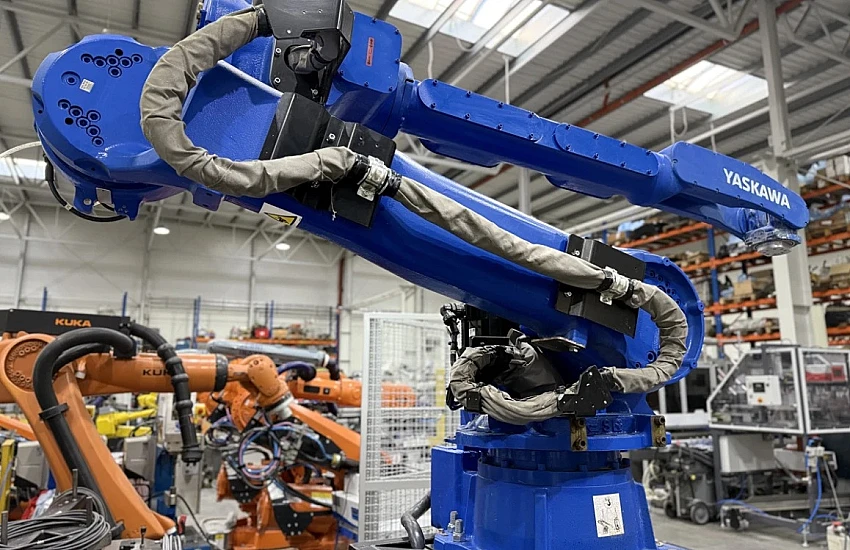

Welding automation is reaching a new level. The Yaskawa Motoman GP20HL is a welding robot that combines precision, speed, and reliability, meeting the needs of modern manufacturing plants.

1. Introduction

What is the Yaskawa Motoman GP20HL?

The Yaskawa Motoman GP20HL is an advanced robotic arm, one of the most modern solutions in industrial robotics. It is an innovative welding robot designed for companies striving for full welding automation. Thanks to its design and technical parameters, the robot guarantees high repeatability, precision, and reliability even in the most demanding operating conditions.

The device works well in large industrial plants and medium-sized companies, which want to increase their competitiveness.

They are doing this by implementing technologies compliant with Industry 4.0. Batch production, which requires a constant pace and consistent quality, becomes more efficient and less susceptible to human error. The GP20HL is a response to growing market demands, where not only speed of execution but also production optimization and full process control are crucial.

A Brief History of Yaskawa

Yaskawa Electric Corporation was founded in Japan in 1915 and has been setting standards in industrial automation, drives, and robotics for over 100 years. The company was a pioneer in developing advanced control systems and manufacturing process automation. Today, Yaskawa is a global leader, present in all major markets, and its solutions operate in thousands of industrial plants worldwide. This brand's robots are synonymous with reliability and quality, and the integration of systems supplied by Yaskawa guarantees smooth collaboration within modern production lines.

2. Advantages of the Yaskawa Motoman GP20HL Robot

Implementing the Yaskawa Motoman GP20HL robot is an investment that brings tangible benefits to companies. Its design not only ensures maximum performance and durability but also easy integration of the systems into existing infrastructure. The robot is compatible with modern CNC control systems, making it a universal solution for both traditional factories and fully robotic production cells.

Key Advantages:

- Welding Precision and Repeatability

Thanks to modern drives and control systems, the robot guarantees consistent weld quality with every work cycle. This is crucial in industries where not only aesthetics but, above all, the durability of joints is crucial – for example, in steel structures or machine components.

- High Efficiency and Increased Productivity

Shorter work cycles translate into a real increase in production line efficiency. The GP20HL allows for more orders to be processed simultaneously, which translates into faster contract fulfillment and shorter waiting times for customers.

- Cost Reduction and Optimization

Workflow automation minimizes rework and material waste. This allows companies to achieve significant cost reductions while implementing effective cost optimization at every stage of the production process.

- Easy Integration with Production Lines

The GP20HL has been designed to work seamlessly with existing automation systems. Integration of control and communication systems with other machines is quick and seamless, significantly shortening implementation time.

- Safety and Ergonomics

The robot handles the most dangerous and monotonous processes, such as arc welding, improving employee safety. This allows companies to not only reduce the risk of accidents but also improve work ergonomics and employee comfort.

- Flexible Applications

The GP20HL is suitable for a wide range of processes – from welding metal components in small batches to complex, large-scale serial production. Its versatility makes it suitable for use in the automotive, machinery, metalworking, and construction industries.

3. Technical Specifications

The technical specifications of the Yaskawa Motoman GP20HL, available in our offer, demonstrate the full range of capabilities of this advanced solution. The device's parameters have been designed to meet the demands of the modern welding industry – from high-precision movements to high-speed operation.

Technical Specifications:

- Type: YR-1-06VXHL20-A00

- Year of Manufacture: 2020

- Serial Number: R19750-784-1

- Payload Capacity: 20 kg

- Weight: 560 kg

- Axles: 6

- Reach: 3124

4. Robot Applications in Industry

The Yaskawa Motoman GP20HL robot is used in various industries where high quality, repeatability, and efficiency are essential. Thanks to its design and compatibility with modern systems, it can be easily implemented in both traditional lines and advanced automation projects.

Key Application Areas:

- Metalworking – welding of steel structures, profiles, and components requiring maximum accuracy.

- Automotive – mass production of frames, bodies, and car components, where repeatability and precision are essential.

- Machinery – creating components for devices where durability and high quality are key.

- Mass and large-scale production – the GP20HL was designed for processes requiring consistent repeatability and high efficiency.

- Industry 4.0 – the robot integrates seamlessly with intelligent monitoring and management systems, facilitating full system integration. Automated lines – the ability to work within production cells equipped with modern CNC control systems, enabling the creation of fully robotic stations.

5. Summary

The Yaskawa Motoman GP20HL is an advanced welding solution that combines high precision, efficiency, and extensive application flexibility. Thanks to its modern design and easy integration with production lines, the robot perfectly aligns with the Industry 4.0 concept and supports full welding automation.

For companies investing in automation, this means:

- stable and repeatable weld quality,

- shortened order lead times and increased productivity,

- effective production optimization,

- greater employee safety in processes requiring, among other things, arc welding.

This solution is suitable for both large factories and medium-sized enterprises seeking to increase their competitiveness in the market.

If you care about modern, effective and reliable automation of welding processes, the Yaskawa Motoman GP20HL is a choice that will allow your company to reach a higher level of production.