Table of Contents

Production automation is one of the key directions of industrial development today. Companies are seeking solutions that will allow them to increase efficiency, reduce costs, and maintain the highest quality. One device that meets these requirements is the Yaskawa Motoman UP50N – an industrial arm designed with precision, reliability, and application flexibility in mind.

1. Introduction

What is the Yaskawa Motoman UP50N?

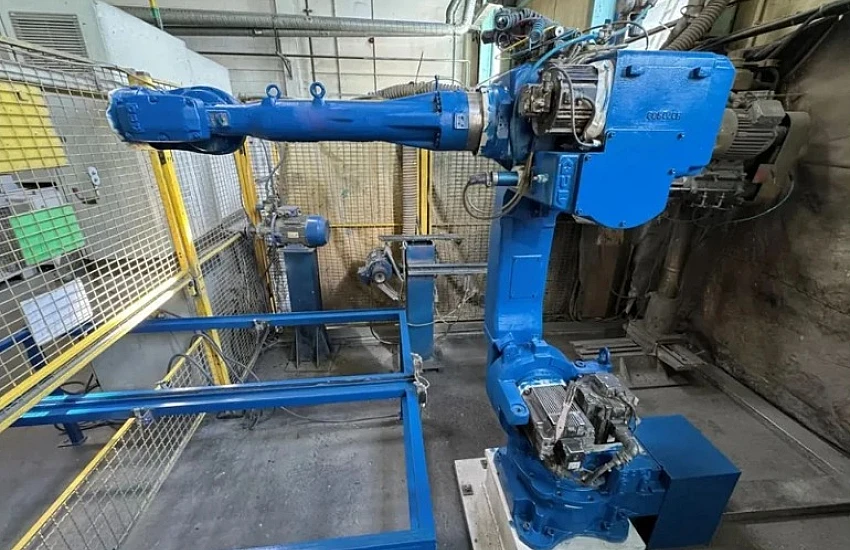

The Motoman UP50N is a modern industrial arm that plays a key role in industrial automation processes. Designed for robotic systems where reliability, speed, and precision are key. Thanks to its technical parameters and robust construction, it is ideal for welding automation, assembly, palletizing, and workpiece handling.

This model stands out for its compact design, high movement accuracy, and high payload capacity. This makes it a versatile solution for plants of all production scales. Implementing the UP50N allows for process optimization and increased efficiency, which translates directly into cost reduction and improved production quality.

A Brief History of Yaskawa

Yaskawa Electric Corporation is a pioneer in industrial automation. Founded in 1915 in Japan, the company has been providing solutions supporting the development of modern manufacturing for over a century. Its Motoman brand was introduced in 1977, becoming a symbol of innovation in robotics.

Thanks to its global presence and experience, Yaskawa provides technologies enabling production line integration, providing companies with greater flexibility and efficiency.

2. Advantages of the Yaskawa Motoman UP50N

When deciding to implement a robotic system, companies pay particular attention to parameters that truly impact performance. The Yaskawa Motoman UP50N combines innovative solutions with proven quality. Its key advantages include:

- High precision and repeatability

The UP50N model provides positioning accuracy at a level that guarantees repeatable process quality. This makes it ideal for tasks requiring precision, such as welding and assembly.

- High payload capacity and wide reach

The UP50N arm features a significant payload capacity and a wide working range. This allows it to handle heavier workpieces and perform more complex operations across diverse production lines.

- Compact Design

The robot's compact design facilitates integration into existing workstations. This reduces its footprint and allows it to be used in both small and large production facilities.

- Flexible Applications

The UP50N is used in a wide range of industries – from welding, assembly, and machine maintenance, to palletizing and packaging. This versatility makes it an investment that is suitable for various production areas.

- Energy Efficiency and Reliability

The robot is designed for long-term operation and low energy consumption. Its robust design and proven technological solutions translate into reliable operation, even in continuous operation.

- Increased Production Efficiency

Implementing the UP50N significantly improves the efficiency of production lines. Process automation reduces cycle times, minimizes errors, and supports high product quality.

3. Technical Specifications of the Yaskawa Motoman UP50N

The Yaskawa Motoman UP50N, was designed for demanding industrial processes where precision, speed, and reliability are paramount. Its technical parameters ensure high efficiency and accuracy, while its robust construction combined with precise control guarantees long life and reliable operation.

Technical Specifications:

- Model: UP50N

- Serial Number: S7M124-1-1

- Year of Manufacture: 2007

- Number of Axes: 6

- Payload Capacity: 50 kg

- Reach: 2061 mm

- Repeatability: ±0.07 mm

- Weight: approx. 570 kg

- Control Unit: NX100

- Components: Control Cabinet, Remote Control

4. Applications of the Yaskawa Motoman UP50N in Industry

Technical specifications are one thing, but the true value of a robot is revealed in its practical use. The Yaskawa Motoman UP50N is used in numerous industries, supporting both automated processes and tasks requiring the highest precision. Below are its most important areas of application.

- Automatic Welding

One of the main areas in which the Yaskawa Motoman UP50N is used is welding processes. Thanks to its high accuracy and repeatability, the device ensures consistent weld quality, reducing errors and production waste. The robot can be used for both arc and spot welding, making it a versatile solution for the metal and automotive industries.

- Precision Assembly

In modern production lines, speed and reliability of assembly are increasingly important. Thanks to its design and control, the UP50N enables precise assembly of even small components. This minimizes the risk of errors and increases workflow speed, which is particularly important in the electronics, machinery, and automotive industries.

- Palletizing and Packaging

The robot offers a robust payload capacity and a long arm reach, resulting in effective automation of palletizing and packaging processes. The UP50N can quickly and consistently stack products on pallets and operate packaging lines. This reduces order turnaround times and relieves employees of repetitive, physically demanding tasks.

- Machine Operation and Parts Handling

Another significant application for the UP50N is operating production machinery. The robot can feed, retrieve, and transfer parts between stations, ensuring continuous production. Its high-speed movement and precision eliminate downtime and reduce the risk of damage to parts, which is crucial in industries requiring high quality and repeatability.

5. Summary

The Yaskawa Motoman UP50N is a modern solution that combines high precision, robust construction, and application flexibility. Its technical parameters and practical capabilities make it a device that supports the development of companies focusing on process automation.

With this model, companies can expect increased efficiency, reduced costs, and improved production quality. It's an investment that allows them to build a competitive advantage and meet the demands of modern industry.